Understanding SLM:

SLM belongs to the powder bed fusion family of additive manufacturing methods. It involves the layer-by-layer deposition of metal powder, selectively melted by a high-powered laser according to a digital design. This precise melting process fuses the particles together, creating fully dense, intricate metal components with exceptional mechanical properties.

Workflow Overview:

1. Design Phase:

The SLM workflow begins with the digital design of the desired component using Computer-Aided Design (CAD) software. Designers have the freedom to create complex geometries optimized for performance and functionality.

2. Pre-processing:

Once the design is finalized, it undergoes pre-processing. This step involves preparing the digital model for printing. Tasks include optimizing support structures, slicing the design into thin horizontal layers, and generating toolpaths that guide the laser's movement during printing.

3. Material Preparation:

High-quality metal powders suited for SLM are crucial for successful printing. Material properties such as particle size, shape, and chemical composition directly impact the final part's quality. Powder handling systems ensure consistency and quality control throughout the printing process.

4. Machine Setup:

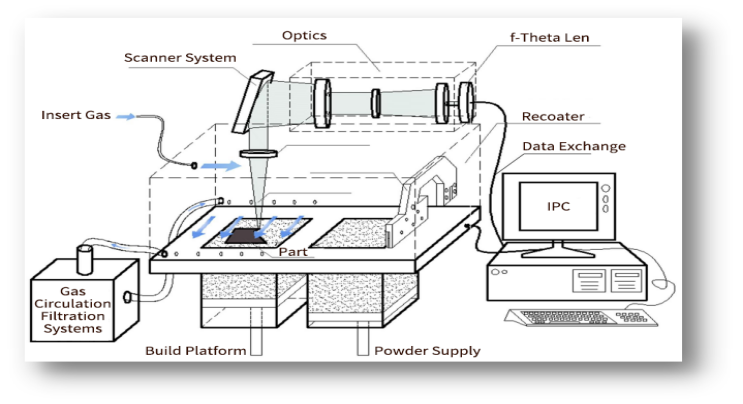

In this step, the SLM machine is prepared for printing. The build chamber is cleaned, and a thin layer of metal powder is evenly spread across the build platform. Precise calibration ensures accurate layer deposition and laser focus throughout the printing process.

5. Printing:

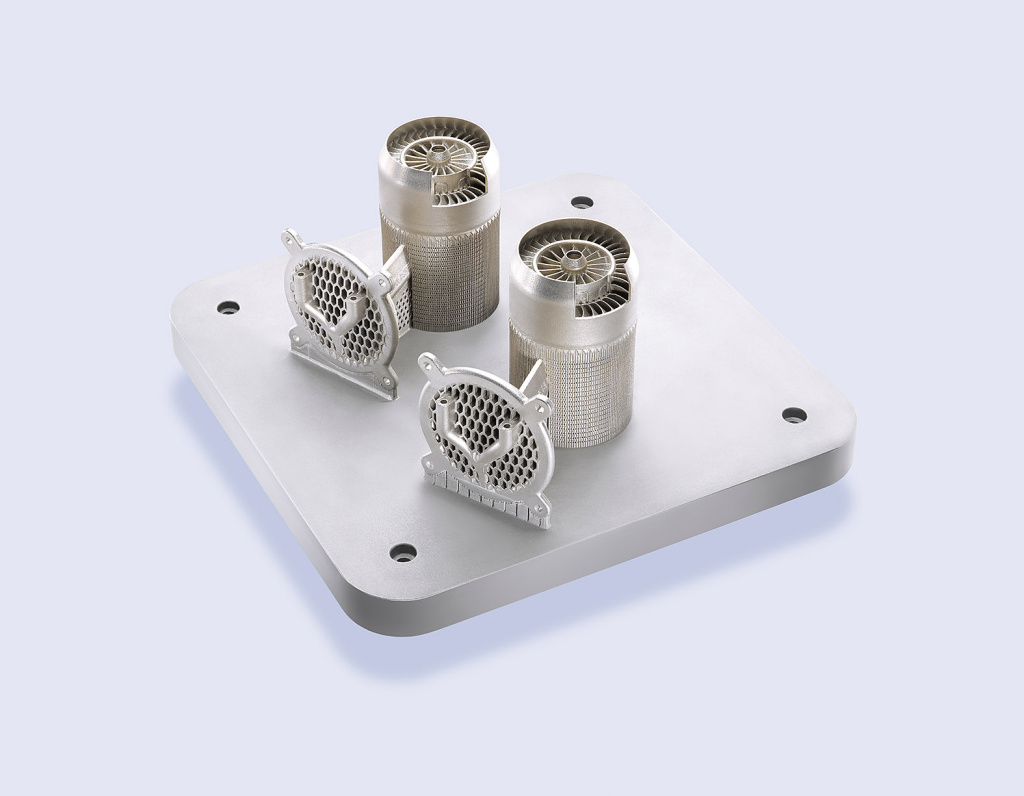

With the setup complete, printing begins. The SLM machine selectively fuses metal powder particles together according to the predefined digital design. A high-powered laser scans each layer, melting the powder in specific areas outlined by the slicing software. The build platform gradually descends as each layer is completed, enabling the creation of complex, multi-layered parts.

6. Post-processing:

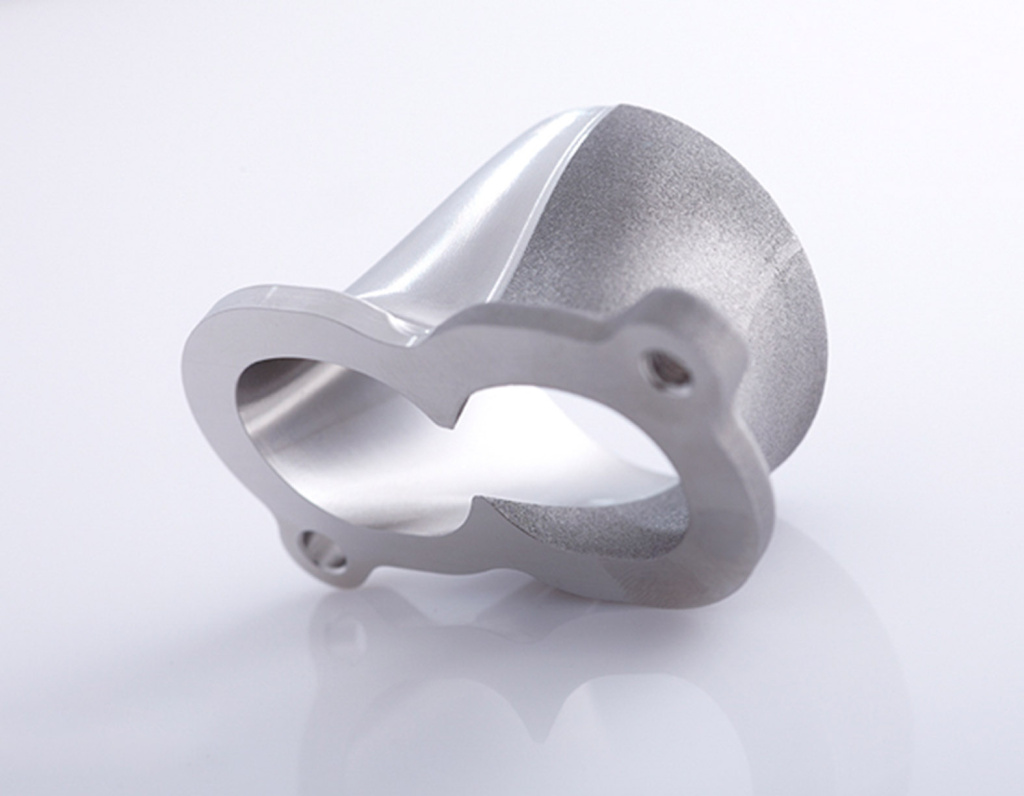

Once printing is finished, the fabricated part undergoes post-processing to achieve the desired mechanical and aesthetic properties. This typically involves removing support structures, heat treatment to relieve residual stresses and improve material properties, surface finishing through machining or polishing, and inspection to ensure dimensional accuracy and quality.

|

|

|

|

7. Quality Control:

Quality control is integral to the SLM workflow. Advanced inspection techniques such as CT scanning, X-ray imaging, and dimensional metrology are employed to verify part integrity, geometry accuracy, and material properties. This ensures that the final components meet stringent industry standards and performance requirements.

Benefits of SLM:

Complex Geometries

SLM enables the fabrication of intricate designs that are difficult or impossible to produce using traditional manufacturing methods.

Material Efficiency

SLM minimizes material waste by only using the necessary amount of metal powder for each component, reducing material costs and environmental impact.

Customization and Rapid Prototyping

SLM allows for on-demand production of customized parts and rapid prototyping, accelerating product development cycles and time-to-market.

High Performance

Parts manufactured through SLM exhibit excellent mechanical properties, including high strength, durability, and corrosion resistance, making them suitable for demanding applications.

Selective Laser Melting represents a cutting-edge manufacturing technology that continues to drive innovation across various industries. By understanding the workflow of SLM, from digital design to quality control, manufacturers can harness its capabilities to produce high-quality, complex metal components with unprecedented efficiency and precision. As advancements in materials and machine technology continue to expand the capabilities of SLM, its role in reshaping modern manufacturing processes is set to grow even further.