The aerospace industry is one of the largest in the country in terms of the number of jobs, the value of fixed assets, the volume of production and sales. The aerospace industry is a component of the country's defense-industrial complex, one of the key elements in the system of ensuring technological progress and national security. AK produces almost all types of aviation and rocket-space equipment, fully satisfying the needs of civil aviation, cosmonautics and the Armed Forces of the country.

Thanks to 3D technology, aerospace companies around the world are optimizing their development and production cycles.

- geometry control

- reverse engineering

- prototyping

- master modeling

- tooling production

- functional parts manufacturing

- development of complex structures, including monolithic structures that were previously formed from many individual components

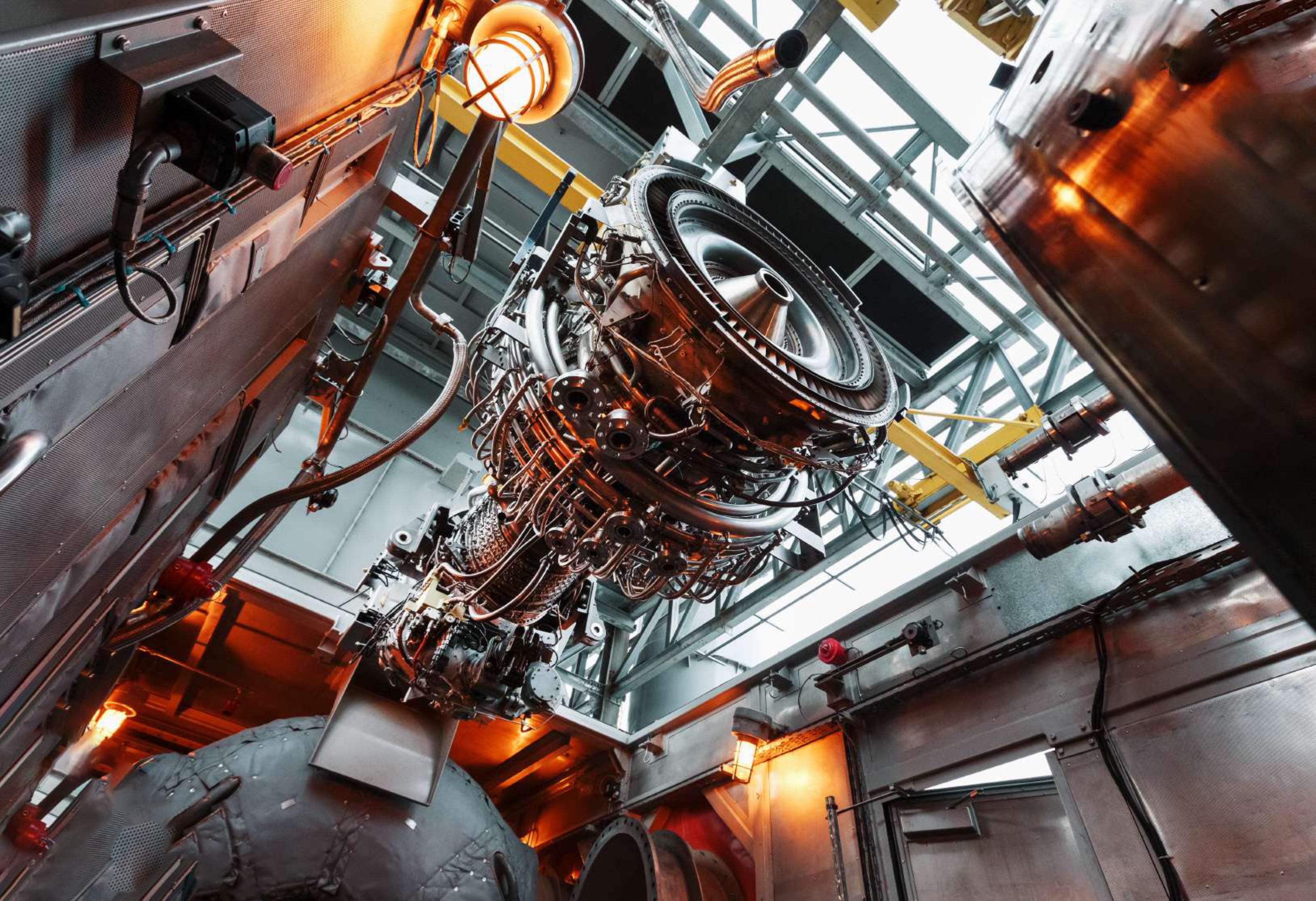

3D printing a rocket engineLEAP 71, an engineering company that applies artificial intelligence (AI) to calculations, has announced the successful test launch of a liquid rocket engine. The engine was designed autonomously, without human input, and then printed in a 3D printer made of copper. The engine was successfully hot-fired at a rocket stand in the UK. |

|

|

The 5 kN (500 kg / 1,124 lb-ft) thrust engine confirmed 20,000 horsepower and passed all tests, including continuous operation. |

|

This is an important milestone for the entire industry. We can now automatically create functional rocket engines and go straight to practical validation From final specification to engine production took less than 2 weeks. With traditional design, this would have taken many months or even years. Designing each successive iteration of the engine takes only a few minutes. |

|

It is a relatively compact engine that would be suitable for the last stage of an orbital rocket. The engine runs on cryogenic liquid oxygen (LOX) and kerosene, a combination used in many modern rocket systems. The engine was printed from copper (CuCrZr) using an EOS M290 metal printer. Copper has a low melting point, but when actively cooled, it allows for the creation of compact, high-performance engines. |

|

|

The engine uses thin cooling ducts swirling around the chamber jacket, with variable cross-sections up to 0.8 mm. Kerosene is forced through the channels to cool the engine. Both fuels are then injected into the combustion chamber. The combustion temperature inside the engine is about 3000ºC, while the engine surface remains below 250ºC due to active cooling. Fuel is injected into the engine using a coaxial vortex injector head. This type of injector is considered to be the most advanced. |