Заказать звонок

Leasing

Calculate equipment leasing

commissioning

We will install, launch and train you to use the equipment

Repair and service

Own service department

3D sand printing technology is used in foundry processes, simplifying small batch casting and new product development processes.

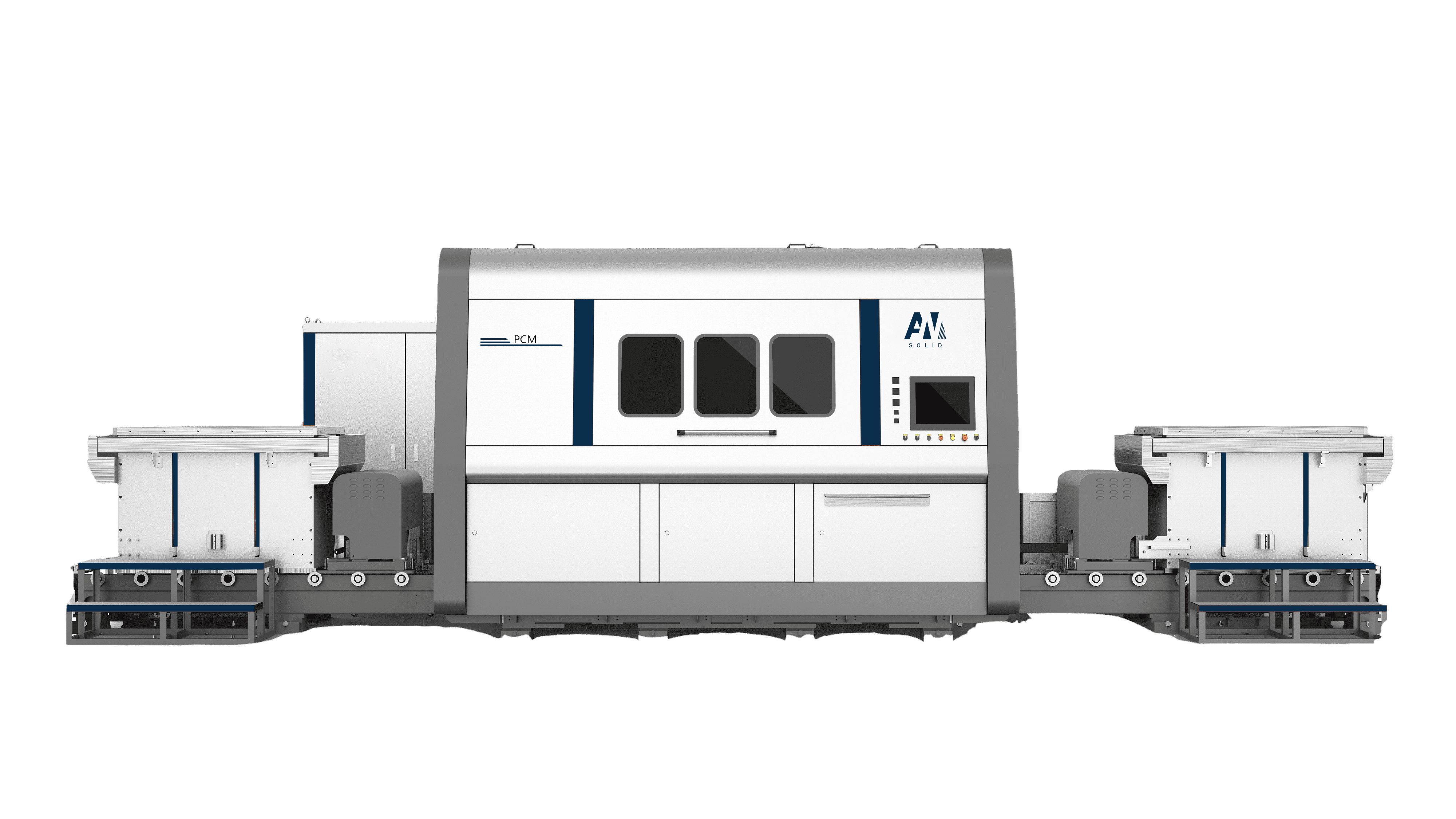

3D sand mold manufacturing (PCM) is one of the most advanced mold making technologies currently available, combining traditional sand casting technology with 3D printing. This technology can quickly create sand molds and cores that are effective for casting complex parts. PCM does not need model tooling, reduces the production cycle and production cost. In addition, using 3D printing to create casting molds utilizes draft-free design, which allows for edits to be made to the casting mold model in a matter of hours.

Advantages of PCM technology: |

|

|

|

| Printing accuracy | ± 0.3 мм |

| Molding efficiency | 120 l/h |

| Print speed | 18 sec/layer |

| Layer thickness | 0.2 - 0.5 mm |